Products

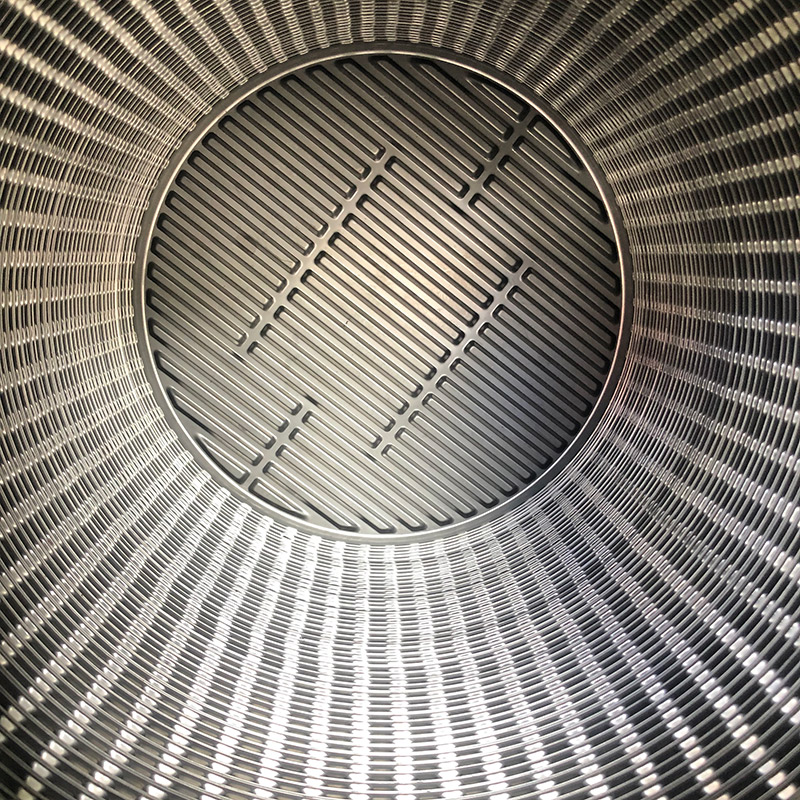

Milk Cooler Stainless Steel Flat Plate Heat Exchanger

Features

The plate heat exchanger has the characteristics of high heat exchange efficiency, high heat recovery rate, small heat loss, small footprint, flexible assembly, simple operation, convenient installation, disassembly and cleaning, long service life, low investment, and safe use. Under the same pressure In the case of loss, the heat transfer coefficient of the plate heat exchanger is 3-5 times higher than that of the tube heat exchanger, the floor area is only one third of the tube type, and the heat recovery rate can be as high as 90%.

Material

1. Stainless steel:

SUS304/SUS304L/SUS316/SUS316L (applicable to acid-base media with serious corrosion conditions, not suitable for conditions containing chloride ions) .

2. Industrial pure titanium: TAE (alkali production, salt production, seawater cryogenic freezing and chloride ion containing serious corrosion conditions).

3. Ultra-low carbon stainless steel: 00Cr18Ni14Mo2Cu2 (organic solvents and occasions with intergranular and chloride ion corrosion).

Process flow

1. Due to the special effect of the plate corrugated surface, the plate heat exchanger makes the fluid flow along the corrugated channel, and the direction of its velocity changes continuously, causing the fluid to arouse a strong end motion at a small flow rate, thus strengthening the transmission. heat process. The heat transfer capacity is effectively improved, and it has the outstanding advantages of compact structure, low metal consumption, high operational flexibility, and long service life.

2 The process of the heat exchanger is assembled by many plates according to certain process and technical requirements of the buyer. When assembling, the plates A and B are arranged alternately, and a mesh is formed between the plates. The gasket seals the hot and cold media in the heat exchanger, and at the same time reasonably separates the hot and cold media without mixing them. The hot and cold fluids in the channel Interval flow can be countercurrent or downstream as required. During the flow, the hot and cold fluids exchange heat through the plate surface to achieve the desired effect.

3.There are many process combinations of plate heat exchangers, all of which are realized by using different reversing plates and different assemblies. Process combination forms can be divided into single process, multi-process and mixed process forms.