Products

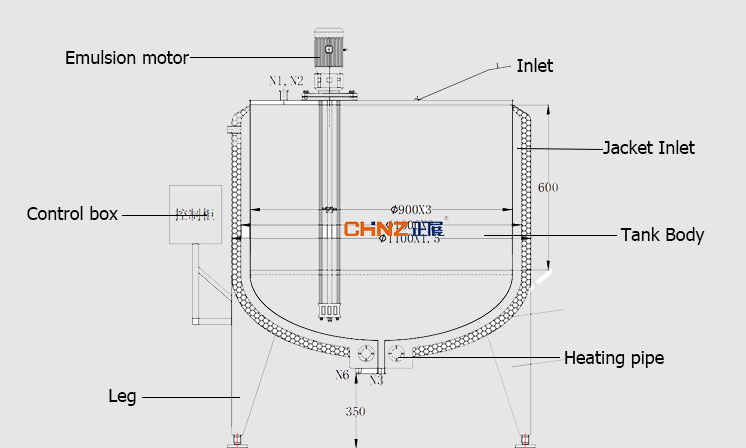

High shear Homogeneous Emulsification Tank Machinery Equipment

Description

·Operating performance

Emulsification tank with accessories (such as manhole ,inlet and outlet and valve etc.) are easy to operate and observe.

·Health Performance

Tank equipped with standard dished top and bottom type.All joints and inside of the tank is mirror finished without any dead angle and cleaned easily(Sanitary design). Surface roughness Ra ≤ 0.22μm.

·Insulation Performance

Insulation material is polyurethane foam, PU thickness up to 50 ~+100 mm, insulation stability (24 h temperature 2 ℃), heat medium low consumption of fast temperature changes can radically improve productivity and reduce the use of cost.

·Appearance Performance

Inner mirror polished and outside mat polished , outside roughness Ra ≤ 0.8μm.

Main Feature

This unit adopts the upper coaxial three-heavy agitator, the hydraulic lifting and opening the cover, the speed of the fast homogenizing agitator: 0-3000r/min (frequency conversion speed regulation), and the slow-speed wall scraping agitator, which automatically adheres to the bottom and wall of the tank. Vacuum suction is adopted, especially for powder materials to avoid dust flying. The whole process is carried out under vacuum conditions to prevent the material from generating air bubbles after high-speed stirring, which can meet the requirements of sanitation and sterility. The system is equipped with a CIP cleaning system, the contact part between the container and the material is made of SUS316L material, and the inner surface is mirror-polished (sanitary).

This unit is easy to operate, stable in performance, good in homogeneity, high in production efficiency, convenient in cleaning, reasonable in structure, small in floor space and high in automation.